Dealing with parameters

Sounds easy enough

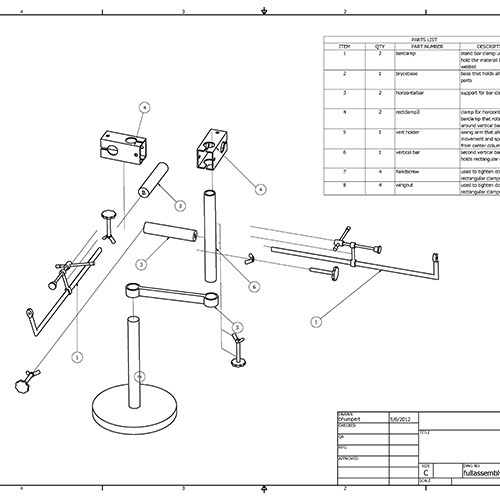

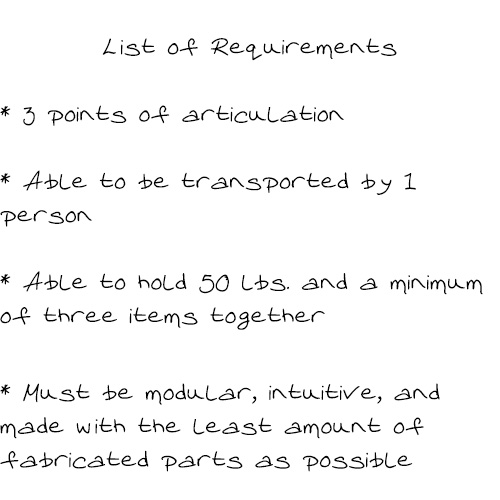

For our senior mechanical engineering design project, we were assigned to make a universal welding fixture that satisfied the requirements listed to the left. Initially, I was a little upset in the fact that it seemed so simple. I thought "Surely we'll finish this in a week and then I'll be done for the semester." Soon enough I found out that this was more of an exercise in "less is more" and that the simpler the design, the better off you will be.